Welding is a fundamental process in various industries, from manufacturing and automotive to aerospace and construction. Ensuring the efficiency, precision, and safety of welding operations is paramount for these sectors. There are various types and styles, the simplest of which support a variety of additional table combinations including Vertical turntables, lift tables, and horizontal rotary tables, often employed in conjunction with advanced railing fixtures, jigs, and other welding accessories. One tool that plays a crucial role in achieving these goals is the modular welding table. In addition, for industries where welding fumes pose health and safety risks, tables with built-in fume extraction systems offer significant advantages. Let’s delve into the importance of modular welding tables and explore the benefits of tables with integrated fume extraction in your industry.

The Significance of Modular Welding Tables

1. Versatility and Flexibility

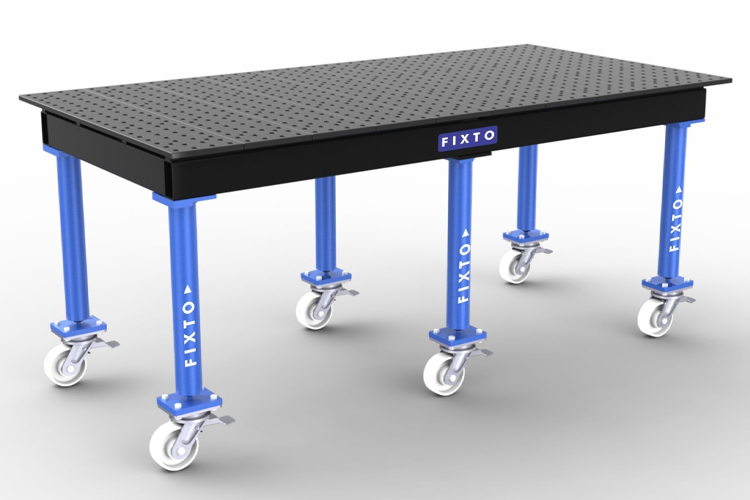

Modular welding tables are known for their versatility. They provide a flexible work surface that can be adapted to various projects and workpieces. This adaptability is a significant advantage for industries that deal with a wide range of welding applications. Welders can easily configure the table to accommodate different sizes, shapes, and materials, making it a valuable asset in industries with diverse welding needs.

2. Precision and Accuracy

In welding, precision is paramount. Welding table manufacturer in Dubai are designed to ensure precise alignment and positioning of workpieces. The grid system of holes or slots on the table surface allows for secure clamping and accurate placement. This feature is especially crucial in industries where high-quality welds are a top priority, such as aerospace and automotive manufacturing.

3. Productivity Boost

Efficiency in the welding process is a key factor in achieving productivity. Modular tables offer quick setup and reconfiguration, reducing downtime between projects. This efficiency is particularly valuable in industries where time is of the essence. When welders can adapt their workstations swiftly, it results in improved overall productivity.

4. Cost Efficiency

Custom fixtures and jigs can be expensive and time-consuming to create for each project. Modular welding tables eliminate the need for these custom solutions, saving both time and money. Small and medium-sized businesses can especially benefit from the cost savings provided by these tables.

5. Safety and Work Environment

A stable and level work surface contributes to a safer working environment. It prevents workpieces from shifting during welding, reducing the risk of accidents and injuries. Safety is paramount in industries where welding processes are part of daily operations.

6. Consistency in Weld Quality

Maintaining consistent weld quality is essential in industries like aerospace and automotive manufacturing, where weld integrity directly impacts product safety and reliability. Modular welding tables enable welders to achieve a high level of consistency in their work, which is critical for the final product’s integrity.

7. Customization and Durability

Modular welding tables can be customized with various accessories like clamps, vices, and tool holders. This flexibility allows welders to tailor their workstations to specific project requirements. Additionally, these tables are built to withstand the rigors of industrial welding, ensuring durability and a long lifespan. Welding tables and accessories in UAE are designed and manufactured by high-quality welds.

Advantages of Weld Tables with Built-in Fume Extraction

While modular welding tables offer a wide range of benefits, some industries face an additional challenge: welding fumes. Welding produces hazardous fumes and gases that can pose health and safety risks to welders. Tables with built-in fume extraction systems provide the following advantages:

1. Health and Safety

The most significant advantage of tables with built-in fume extraction is the protection of welders’ health and safety. These systems effectively remove harmful welding fumes and gases from the workspace, preventing exposure to hazardous substances. This is particularly crucial in industries where worker safety is a top priority.

2. Compliance

In many regions, there are regulations and standards in place regarding the control and extraction of welding fumes. Tables with built-in extraction systems help businesses comply with these requirements, avoiding potential legal issues and ensuring a safe working environment.

3. Improved Air Quality

Effective fume extraction results in cleaner air in the workspace. This not only protects the health of welders but also contributes to a more comfortable and productive working environment. Clean air enhances overall job satisfaction and efficiency.

4. Enhanced Productivity

Better air quality can lead to improved productivity. When welders can work in a comfortable and healthy environment, they are more focused and efficient. This ultimately benefits the productivity of the entire operation.

5. Cost Savings

While there is an initial investment in tables with built-in extraction, the long-term cost savings related to health, safety, and productivity can be significant. Businesses can avoid costs associated with worker health issues, downtime due to fume-related problems, and potential legal fines.

6. Environmental Responsibility

Efficient fume extraction systems not only protect worker health but also reduce the environmental impact of welding. They prevent the release of harmful pollutants into the atmosphere, aligning with the growing emphasis on environmental responsibility in modern industries.

7. Comprehensive Solution

Weld tables with built-in extraction systems provide a comprehensive solution that addresses both welding support and fume control. This integration streamlines the welding process and workspace, reducing the need for separate extraction equipment and simplifying maintenance.

modular welding tables play a vital role in enhancing efficiency, precision, and safety in welding operations across various industries. For industries dealing with welding fumes, tables with built-in fume extraction systems offer essential health and safety benefits, compliance with regulations, and improved productivity. The choice between these two types of tables depends on the specific needs and priorities of your industry, but both contribute to the overall success.

Modular Welding Tables: Enhancing Welding Precision and Efficiency

The advent of 3D modular welding tables has revolutionized the welding industry, bringing forth a new era of efficiency and precision. Unlike traditional static surfaces, these tables offer dynamic features that can be adjusted to meet the exacting requirements of welding processes. The versatility of modular welding tables extends to various types and styles, allowing for an array of table combinations. These combinations include vertical turntables, lift tables, and horizontal rotary tables, often employed in conjunction with advanced railing fixtures, jigs, and other welding accessories, offering limitless customized solutions for welding needs.

Moreover, contemporary 3D modular welding tables and fixtures are designed with ease of setup and user-friendliness in mind. They seamlessly integrate with clamping components to facilitate the welding process. When considering a welding table, there are several key factors to contemplate:

1. Size of the Welding Table: The dimensions of your welding table should align with the specific requirements of your projects. Opt for a larger modular welding table if your work involves variable project sizes.

2. Welding Table Accessories:

Many welding tables come equipped with built-in clamps that enable welders to secure materials effectively. Additionally, a range of accessories enhances the welder’s capabilities, including:

- Debris-catching trays

- Magnets for material positioning

- Angled rails that act as additional hands to maintain workpieces in precise positions

- Side hooks on some welding tables, ideal for holding welding guns.

3. Portability of the Welding Table: Portable welding tables offer greater versatility than their fixed counterparts. These tables can be conveniently folded flat for easy transportation, making them an excellent choice for welders on the move.

In summary, modular welding tables provide an unprecedented level of precision and efficiency in welding processes, with customizable features that adapt to various welding needs. By selecting the right table size and considering the array of accessories available, welders can enhance their work environment and, ultimately, their productivity. Additionally, portable welding tables offer the flexibility needed for on-the-go welding projects, catering to the dynamic demands of the industry.

To learn more about Dot Peen Marking Machine: What Is It? Services and their importance in today’s markets.