Universal Bender

- Home / Products / Bending & Forming / Universal Bender

Download our complete Company Profile

GET A QUOTE

OVERVIEW

Universal Bender in UAE

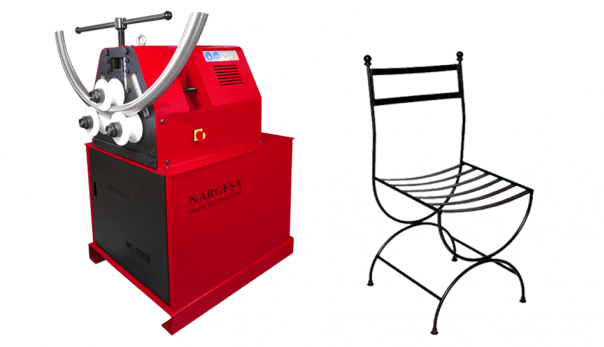

Ring roller bender section machine MC150B

Features

Made of machined steel, with two traction rollers, hardened gear transmission

Maximum capacity for bending round pipe: 2″ inches or 50 mm.

The MC150B pipe bender is meticulously designed to achieve optimal performance while minimizing manufacturing costs in the process of bending various pipes and profiles. This versatile machine is engineered to handle a wide range of profiles, including flat bars, T-profiles, rolling U-profiles, bending angles, solid rods in square and round forms, spiral tubes, and pipes in square, rectangular, or round shapes. It’s suitable for working with different materials such as iron, carbon steel, stainless steel, brass, copper, and aluminum. The applications for these bending operations are diverse, ranging from crafting items like greenhouses, tables, chairs, car guards, doors, windows, railings, and fences, to numerous other metal products. Book your Universal Bender in UAE.

Specifications

- The equipment features two drive rollers, with the two lower rollers being motorized and knurled for improved grip. It ensures a secure transmission through the use of flat hardened pinions. The axes have a diameter of 40 mm, with a useful length of 74 mm and a center distance of 230 mm between the lower axes. The maximum capacity for bending round pipes is 2 inches or 50 mm.

- Bending adjustments are facilitated by the upper shaft, enabling the curving of tubes and large-diameter profiles without causing deformation. The MC150B section bending machine is supplied with 9 rollers and standard washers that can be combined to accommodate various profile types, including square pipes, rectangles, square bars, round and rectangular bars, U profiles, T profiles, angles, flat bars, and edged bars. Special rollers are required only for specific round pipes.

- The upper shaft is equipped with a millimeter scale for precise bending. The machine offers two working positions, both horizontal and vertical, within the same workbench. To control bending deformation when creating spirals and spiral staircases, correction rollers are provided on the sides. There’s a base cupboard for storing rollers and accessories.

- The motor power is 0.75 KW or 1 HP, with a single-phase 230 V voltage supply (other voltages available upon contacting the manufacturer). The rollers operate at a speed of 6 RPM. The lower bench is palletized, making it easy to transport the machine to the workplace or store it when space is limited. The machine is shipped fully assembled, requiring only a power supply connection.

- It is packaged with a steel pallet and a three-layer cardboard box suitable for sea freight. Additionally, there is an option for a fumigated wooden box (NIMF15) if needed.

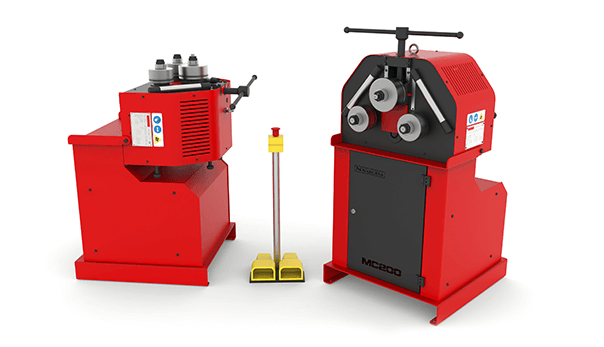

Ring roller bender section machine MC200

Features

- Fabricated in steel, two traction rollers, pinion transmissions, treated and rectified

- Maximum capacity for bending round pipe: 2” 1/2 inches or 63,5 mm.

Constructed from welded and mechanized steel sheet, this machine stands out as it doesn’t rely on cast iron like its counterparts. It excels in a wide range of applications, from crafting flanges, greenhouses, balusters, tables, chairs, doors, windows, and more, enabling the creation of numerous circular shapes across various profiles. Its remarkable strength, substantial axis diameter, impressive reducer capacity, and other attributes position it as one of the top bending machines available in the market, especially among two-traction roller models. All Nargesa products comply with European directives and CE regulations pertaining to the manufacture of industrial machinery.

Specifications

- This machine is equipped with two traction rollers, with the two lower rollers featuring knurling and motorization for enhanced traction. It ensures secure transmission through the use of treated and flat pinions. The machine boasts treated and rectified steel axes with a diameter of 40 mm and a useful axis length of 74 mm. The center distance between the lower axes is 286 mm.

- It can efficiently handle a maximum capacity for bending round pipes of up to 2 1/2 inches or 63.5 mm. Bending operations are regulated through the upper axis, enabling distortion-free bending even for larger pipes and profiles. The machine comes with 9 standard rollers and washers, allowing for the creation of a wide variety of profiles, including square pipes, rectangular shapes, solid square bars, round and rectangular bars, U profiles, T profiles, angles, flat bars, and edge flat bars.

- A millimeter scale on the upper axis facilitates precise bending regulation. The machine offers both vertical and horizontal working positions within the same table. To ensure precise bending and create spiral bends, it includes side corrector rollers. The motor power is 1.1 KW or 1.5 HP, with a voltage supply of 3-phase 230/400 V. For single-phase machines, a quotation can be requested.

- Rollers operate at a speed of 8 RPM, and the lower bench is palletized for easy transportation to the workplace or for storage in limited space. The machine is shipped fully assembled, requiring only a power supply connection. It is packaged with a steel pallet and a three-layer cardboard box suitable for sea freight. An optional fumigated wooden box (ISPM15) is available upon request

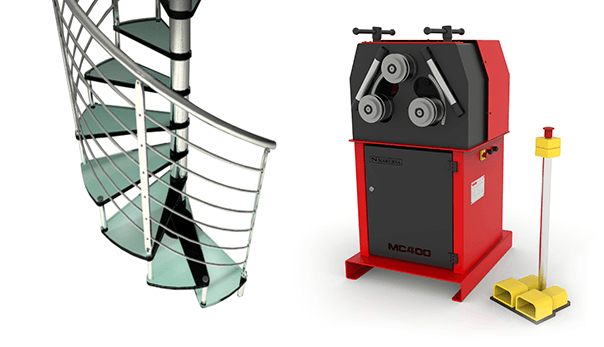

Profile bending machines MC400

Features

- made of steel, it has got three traction rollers, pinion transmissions, treated and rectified axis.

- Maximum capacity for bending round pipe: 2” 1/2 inches or 63,5 mm.

Crafted from welded and precision-engineered steel sheet, this machine stands apart by avoiding the use of cast iron, setting it apart from others. It excels in various applications, including creating flanges, greenhouses, balusters, tables, chairs, doors, windows, and shaping a multitude of circular forms across diverse profiles. Its exceptional strength, substantial axis diameter, impressive reducer capacity, and additional features collectively establish it as one of the top bending machines available in the market. In particular, it falls within the category of three traction rollers, an indispensable prerequisite for working with pipes and achieving flawless outcomes.

Specifications

- Featuring three traction rollers, this machine is indispensable for bending round pipes while ensuring a smooth surface that prevents any damage to the pipe or profile. It guarantees a secure transmission through the use of treated and flat pinions. The machine’s axes are crafted from treated and rectified steel, with a diameter of 40 mm and a useful axis length of 80 mm.

- It can efficiently handle a maximum bending capacity in round pipes of up to 2-1/2 inches or 63.5 mm. Bending operations can be finely regulated, separate from the lower rollers, allowing for bending in smaller diameters and maximizing material usage compared to other bending machines. Equipped with nine standard rollers, it accommodates a wide range of profile types, including square pipes, rectangles, solid square bars, round and rectangular shapes, U profiles, T profiles, angles, flat bars, and edge flat bars. The rollers have a diameter of 130 mm and millimeter scales for precise positioning.

- This machine offers both vertical and horizontal working positions, adaptable to the working table. To ensure accurate bending, side corrector rollers are included. The engine power is 1.1 KW or 1.5 HP, with a 3-phase tension of 230/400 V. For single-phase machines, a quotation can be requested.

- Rollers operate at a speed of 7 RPM, and the lower table is palletized for easy transportation to the work site or for storage. The machine is shipped fully assembled and packaged with a steel pallet and a three-layered cardboard box suitable for sea freight. An optional wooden packaging complying with NIMF15 standards is available.

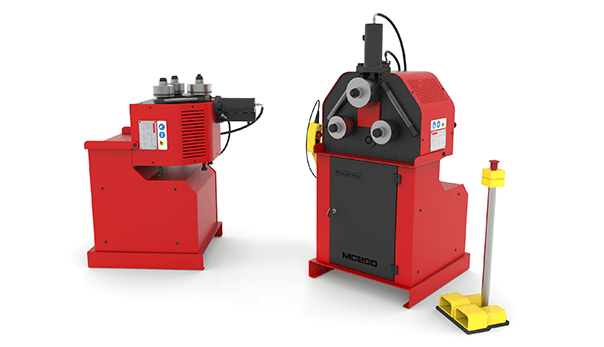

Hydraulic section bending machine MC200H

Features

- made of steel, it has got three traction rollers, pinion transmissions, treated and rectified axis.

- Maximum capacity for bending round pipe: 2” 1/2 inches or 63,5 mm.

Designed and created from welded and precision-engineered steel sheet, this machine sets itself apart by not relying on cast iron, a distinguishing feature from its counterparts. It excels in a wide range of applications, including crafting flanges, greenhouses, balusters, tables, chairs, doors, windows, and forming numerous circular shapes across various profiles. Its exceptional durability, axis diameter, reducer capacity, and additional features position it as one of the finest bending machines available, particularly within the category of two-traction rollers. It’s worth noting that all Nargesa products adhere to European directives and CE regulations concerning the manufacturing of industrial machinery.

Specifications

- Ensuring a secure transmission, this machine employs treated and flat pinions. The axes are crafted from treated and rectified steel, featuring a diameter of 40 mm and a useful axis length of 74 mm. The center distance between the lower axes measures 286 mm.

- It can effectively handle a maximum bending capacity in round pipes of up to 2 1/2 inches or 70 mm. Bending operations are regulated through a hydraulic piston in the upper axis, enabling distortion-free bending for larger pipes and profiles without undue effort. The machine comes equipped with 9 standard rollers and washers, facilitating the creation of a wide variety of profiles, including square pipes, rectangles, solid square bars, round and rectangular shapes, U profiles, T profiles, angles, flat bars, and edge flat bars.

- The machine features a course end with a millimeter scale for convenient adjustment of bending limits, offering a simple, practical, and reliable method. It provides the flexibility to work in both vertical and horizontal positions on the same table. Additionally, side corrector rollers are included to ensure precise bending, particularly for creating spiral bends.

- The machine is powered by an engine with 1.85 KW or 2.5 CV. It operates at a 3-phased tension of 230/400V, with the option to request a quotation for single-phased machines. The rollers maintain a speed of 8 RPM.

MC550 section and tube bending machine

Features

Maximum capacity for bending round pipe: 3” inches (76,2 mm) or 80 mm.

Constructed from welded and meticulously machined sheet steel, this machine exhibits exceptional durability and stability. Its applications span a wide range, including the manufacture of flanges, greenhouses, railings, large-scale structural components for buildings such as circular beams for roofs, domes, bridge abutments, metal pergolas, curved marquees, and structures for tunnels. Additionally, it excels in the production of urban amenities like street lamps, roundabout protections, bicycle parking stands, tree protectors, railings, public transport marquees, bollards or movable bollards, children’s playground equipment, and a variety of circular forms in different sizes and profiles of sections and tubes. With its impressive capacity, versatility, advanced control panel, and integration of 4.0 technology, the MC550 bender proves itself as an indispensable tool not only for your company, but also for other discerning clients.

Specifications

- The machine is furnished with nine standard rollers, enabling the production of a wide range of profiles, including square pipes, rectangles, solid square bars, round and rectangular shapes, U profiles, T profiles, angles, flat bars, and edge flat bars. Optional rollers are available for round pipes or tubes (see optional accessories at the bottom of the page).

- It is meticulously designed to support mass production through control mechanisms that save the roller positions for reproducing specific operations without the need for longitudinal positioning control.

- The machine offers a maximum bending capacity in round pipes of 3 inches (76.2 mm) or 80 mm, thanks to the inclusion of three traction rollers with a smooth surface to safeguard the integrity of the pipes or profiles.

- Safe transmission is assured through tempered planetary pinions driven by induction, and the axles are crafted from tempered and rectified F-154 steel. The machine operates using an electrohydraulic drive system, with axle diameters measuring 50 mm and a net axle length of 90 mm. The outer roller diameter is 170 mm.

- Bend regulation is independent of the lower rollers, allowing for smaller diameter bends and a more efficient utilization of materials compared to pyramidal bending machines. The machine features electronically-controlled asymmetric roller positioning, and it comes equipped with an ESA S625 panel.

- The main motor is rated at 1.5 KW or 2 CV, while the hydraulic motor unit is rated at 0.75 KW or 1 CV. The electrical voltage required is 230 V single phase, and the roller speed is adjustable, ranging from 3 to 7 RPM.

- The machine is placed on a palletized lower table for easy transportation to the worksite or storage. It is packaged in a wooden pallet and a three-layered cardboard box suitable for sea freight. An optional wooden packaging that complies with NIMF15 standards is also available.

MC650 section and pipe bending machine

Features

- Specially designed to carry out mass production through the control, which saves the position of the rollers in each curve to repeat the same operations later, without longitudinal positioning control. It is ideal for manufacturing flanges, greenhouses, railings, large structures for construction etc

- Maximum capacity for bending round pipe: 4” inches or 101,6 mm.

This machine is built from strong and stable welded and machined sheet steel. It’s great for making various things like flanges, greenhouses, railings, big building structures, street lamps, roundabout protections, bicycle stands, and much more. The MC650 bender has the capacity, flexibility, control panel, and modern 4.0 technology to be an excellent choice for bending tasks, not just for your company but for others too.

Specifications

- This machine features nine standard rollers, allowing for the creation of various profiles, including square pipes, rectangles, solid square bars, round and rectangular shapes, U profiles, T profiles, angles, flat bars, and edge flat bars. Additional rollers for round pipes or tubes can be provided as optional accessories (refer to the optional accessories section at the bottom of the page).

- It is specially designed for efficient mass production, thanks to a control system that saves the roller positions during each bend, making it possible to replicate the same operations later without requiring longitudinal positioning control.

- The machine has a maximum bending capacity for round pipes of 4 inches or 101.6 mm. It is equipped with three traction rollers, essential for bending round pipes while ensuring a smooth surface to protect the integrity of the pipe or profile.

- Reliable transmission is achieved through tempered planetary pinions driven by induction. The machine’s axles are crafted from tempered and rectified F-154 steel. It operates using an electrohydraulic drive system, with a 65 mm diameter for the lower axles and an 80 mm diameter for the upper axle. The net length of the axles is 130 mm, and the outer roller diameter is 202 mm.