Efficiency and safety are paramount, Material Magnetic Lifters have emerged as a game-changer in the realm of material handling in UAE. With their exceptional strength, ease of use, and enhanced safety features, these innovative devices are revolutionizing the way businesses handle heavy loads and streamline their operations. Let’s delve deeper into the benefits of using Material Magnetic Lifters and their widespread applications across various industries in the UAE.

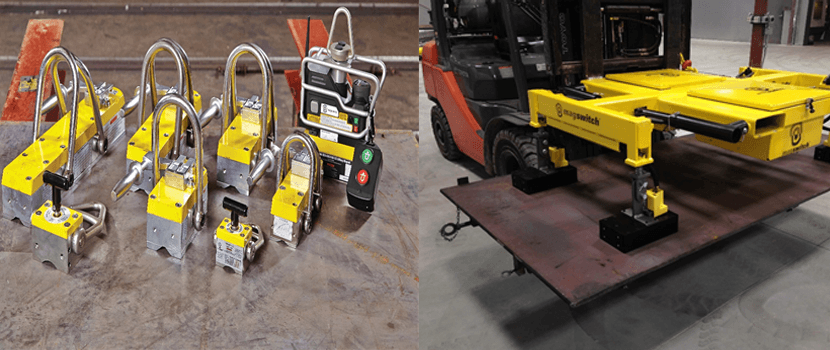

Supports Heavy Loads: One of the most notable advantages of Material Magnetic Lifters in UAE is their ability to support heavy loads with ease. These lifters harness the power of magnets to securely grip ferrous materials, such as steel plates, bars, and components, allowing for the effortless lifting and transportation of heavy loads. Whether it’s in steel fabrication, construction, or manufacturing industries, Material Magnetic Lifters excel in handling heavy materials, minimizing manual labor and maximizing productivity.

Easier to Use Than a Hoist: Unlike traditional hoists that require complex rigging and manual operation, Material Magnetic Lifters offer a simpler and more user-friendly solution for material handling tasks. With intuitive controls and straightforward operation, these lifters can be easily toggled on and off, allowing operators to lift and release loads with precision and efficiency. This ease of use translates to increased productivity and reduced operator fatigue, making Material Magnetic Lifters a preferred choice for businesses seeking streamlined material handling solutions.

Toggle On and Off: Material Magnetic Lifters feature a convenient toggle mechanism that allows operators to easily activate and deactivate the magnetic force as needed. This enables precise control over the lifting process, allowing for seamless positioning and adjustment of materials without the need for manual intervention. Whether lifting individual items or arranging bulk materials, the ability to toggle the magnetic force on and off enhances operational flexibility and efficiency.

Does not Require Electricity: Unlike some traditional lifting equipment that relies on electricity to operate, Material Magnetic Lifters operate solely on the power of magnets, making them a cost-effective and environmentally friendly solution. This eliminates the need for electrical connections or power sources, reducing energy consumption and maintenance requirements. As a result, businesses can enjoy greater operational efficiency and cost savings while minimizing their environmental footprint.

Enhanced Safety: Safety is a top priority in any industrial setting, and Material Magnetic Lifters are designed with safety features to minimize risks and ensure the well-being of workers. By securely gripping materials with powerful magnets, these lifters prevent slippage and instability during lifting and transportation, reducing the risk of accidents or injuries. Additionally, their intuitive controls and ergonomic design minimize operator fatigue and strain, further enhancing workplace safety.

In addition to their benefits in material handling, the use of magnetic filtration in industries such as aerospace, automotive, and food processing is becoming increasingly prevalent. Magnetic filtration utilizes magnetic fields to separate magnetic particles from liquid streams, improving product quality, equipment lifespan, and maintenance efficiency.

Material Magnetic Lifters represent a versatile and efficient solution for material handling tasks in the UAE. With their exceptional strength, ease of use, and enhanced safety features, these innovative devices empower businesses to optimize their operations, increase productivity, and prioritize workplace safety. Embracing Material Magnetic Lifters is key to staying ahead in today’s competitive industrial landscape and unlocking new levels of efficiency and performance.

Magnetic filtration, a process that utilizes magnetic fields to remove magnetic particles from fluid streams, plays a crucial role in improving process efficiency and product quality across various industrial applications. Let’s explore how magnetic filtration is employed in different industries to enhance operations and outcomes:

Automotive Industry: In the automotive industry, magnetic filtration is widely used to maintain the cleanliness and performance of lubricants, hydraulic fluids, and coolant systems. By capturing ferrous contaminants and metal fines, magnetic filters prevent engine wear, reduce friction, and extend the lifespan of automotive components. This helps improve the reliability and durability of vehicles, leading to higher customer satisfaction and lower maintenance costs.

Food Processing Industry: In the food processing industry, maintaining hygiene and product quality is paramount to ensure consumer safety and compliance with regulatory standards. Magnetic filtration is employed to remove ferrous contaminants from raw materials, ingredients, and processing equipment. By effectively capturing metal fragments and foreign particles, magnetic filters prevent product contamination, safeguarding the integrity and purity of food products. This enhances food safety and quality assurance, helping food processors meet stringent regulatory requirements and consumer expectations.

Pharmaceutical Industry: In pharmaceutical manufacturing, maintaining the purity and integrity of pharmaceutical products is critical to ensure their safety and efficacy. Magnetic filtration is utilized to remove metal impurities from pharmaceutical ingredients, solvents, and processing equipment. By eliminating ferrous contaminants and metal fines, magnetic filters help prevent product contamination and ensure the quality and purity of pharmaceutical formulations. This is essential for complying with regulatory standards and maintaining consumer trust in pharmaceutical products.

Water Treatment Industry: In the water treatment industry, magnetic filtration is employed to remove iron, manganese, and other metal contaminants from water sources. Magnetic filters capture ferrous particles and magnetic ions, preventing them from entering downstream treatment processes and causing equipment fouling or product contamination. By improving the quality of treated water, magnetic filtration enhances the efficiency and performance of water treatment systems, ensuring the delivery of clean and safe drinking water to consumers.

Aerospace Industry: In the aerospace industry, precision and cleanliness are paramount for maintaining the integrity and performance of components. Magnetic filtration is used to remove ferrous contaminants from lubricants, hydraulic fluids, and coolant systems, ensuring that critical machinery such as engines, turbines, and hydraulic systems operate smoothly and reliably. By eliminating abrasive particles and preventing component wear, magnetic filtration helps extend the lifespan of aerospace equipment and reduces the risk of costly failures.

Overall, magnetic filtration offers a versatile and effective solution for improving process efficiency and product quality across diverse industrial applications. By harnessing the power of magnetic fields to remove contaminants, magnetic filters help industries maintain cleanliness, enhance equipment performance, and uphold quality standards, ultimately contributing to operational excellence and customer satisfaction.

To know more about Explore Our Range of Insulation Pins and Welding Machines in UAE