When it comes to acquiring industrial equipment to support your construction or industrial project in the UAE, companies face a vital choice — rental or purchase? With increasing demand across sectors such as manufacturing, fabrication, and infrastructure, this decision can significantly impact both your financial planning and operational flexibility.

In the fast-evolving industrial landscape of the UAE, Industrial Machinery Rentals have gained popularity as a smart, flexible solution. However, there are still compelling reasons to consider buying, especially for high-demand, specialized equipment like laser cutting machines.

Let us discuss the pros and cons of renting vs purchasing, and help to clarify which option could be more beneficial for your company.

The UAE Industrial Landscape: A Short Overview

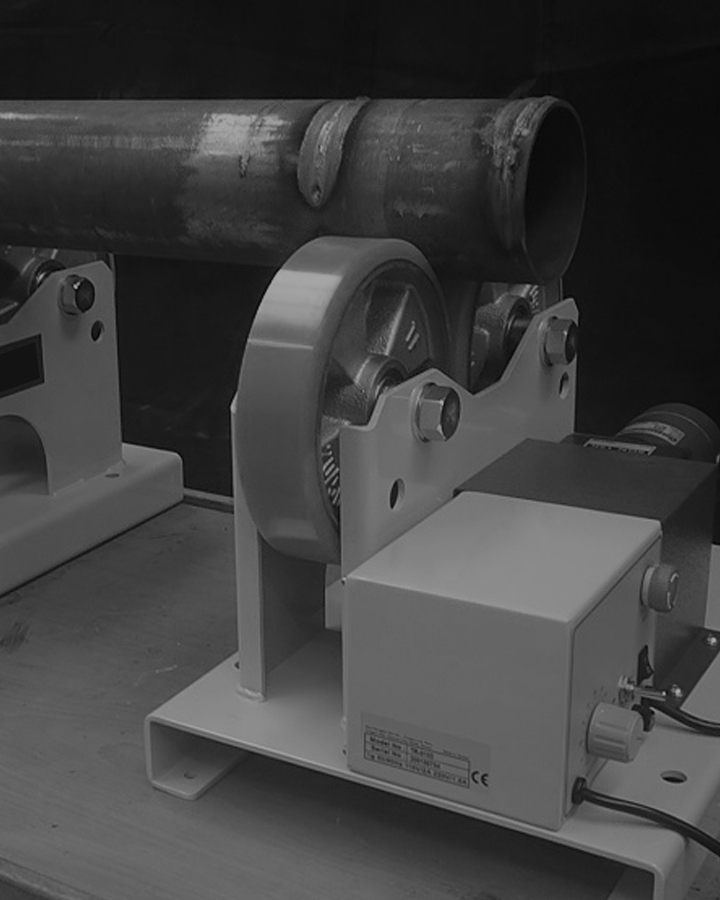

The UAE has become a hub for industrial innovation, driven by large-scale infrastructure projects, a booming construction sector, and government initiatives promoting manufacturing. Businesses involved in metal fabrication, signage, automotive components, and custom manufacturing are increasingly reliant on advanced machinery such as CNC machines, press brakes, and laser cutting machines.

As project timelines tighten and precision requirements increase, companies must balance cost-efficiency with access to cutting-edge tools, making the rent vs. buy decision more relevant than ever.

Pros of Renting Industrial Equipment

1. Lower Initial Investment

Renting industrial equipment significantly reduces upfront costs. This is especially beneficial for startups or companies working on short-term projects that don’t justify a major capital investment.

2. Access to the Latest Technology

Rental providers like Rockwood Machinery offer access to the latest industrial machinery rentals in UAE, including modern laser cutting machines. Renting allows businesses to use cutting-edge technology without committing to long-term ownership.

3. Reduced Maintenance Responsibility

Maintenance and repair obligations will typically be taken over by the rental company. This can result in fewer downtimes and lower operating expenses, allowing your team to focus on productivity instead of technical upkeep.

4. Flexibility for Project-Based Needs

Renting is ideal for companies that handle diverse or seasonal projects. You can scale your machinery fleet up or down based on project requirements, without tying up capital in unused assets.

5. Tax Advantages

Rental costs are generally treated as operational expenses, which may offer more favorable tax deductions compared to capital depreciation on purchased assets.

Pros of Buying Industrial Equipment

1. Long-Term Cost Efficiency

If your operations involve continuous, long-term use of certain machines, purchasing may be more economical in the long run. Owning eliminates recurring rental costs, particularly for high-usage equipment.

2. Full Control Over Equipment

Ownership gives you the freedom to modify, customize, and operate equipment without restrictions. This can be particularly advantageous for specialized machines like laser cutting machines, which often require tailored configurations.

3. Asset Value and Resale Potential

Purchased equipment is a tangible asset on your balance sheet. While machinery depreciates over time, well-maintained equipment can still offer strong resale or trade-in value.

4. Increased Availability

With owned equipment, you’re never at the mercy of rental availability. This guarantees immediate access when your projects demand fast turnaround.

Key Considerations Before Making Your Decision

Before choosing to rent or buy, evaluate the following:

- Frequency of Use: Is the machine required daily, occasionally, or only for specific projects?

- Budget: Do you have capital available for a purchase, or is preserving cash flow more critical?

- Project Duration: Will you be continuing to use the machine after the duration of your project?

- Technology Requirements: Do you need the latest features or will standard equipment suffice?

- Maintenance Capabilities: Do you have in-house technical teams to maintain the equipment?

Renting vs. Buying: What’s Smarter for Laser Cutting Machines?

Laser cutting machines are an essential part of modern fabrication shops across the UAE and offer the speed, precision and flexibility that no other process can provide when cutting metals, plastics and composites.

- If your business handles customized orders, diverse materials, or is expanding rapidly, renting may be the smarter option. It gives you the chance to try out new shapes/models and you can upgrade fairly easily as your needs progress.

- If you operate a high-volume fabrication unit with consistent demand, buying a laser cutting machine makes more sense financially. In terms of a return on investment (ROI), you will eventually find the ROI makes the initial cost worthwhile.

Rockwood Machinery, a trusted name in the UAE, offers both Industrial Machinery Rentals and high-performance laser cutting machines for sale. Whether you’re exploring entry-level fiber laser systems or high-power precision machines, Rockwood’s solutions are designed to meet your production goals without compromise.

Final Thoughts: The Smarter Choice Depends on You

There is no one-size-fits-all answer. The smarter option between renting and buying depends on your specific operational needs, budget constraints, and long-term business strategy.

If flexibility, lower risk, and access to the latest machinery are your top priorities, renting is likely your best move. But if you’re in it for the long haul and need a dedicated machine to power your productivity every day, buying can offer long-term financial and operational advantages.

Whether you choose, partnering with a reliable provider like Rockwood Machinery ensures you get the best of both worlds—top-quality machines and expert support to help you grow.

Explore the smartest choice for your business today. Contact Rockwood Machinery for tailored advice on renting or buying industrial machinery in the UAE.

To continue reading, click: Selecting Materials: Guide for Laser Marking Machines