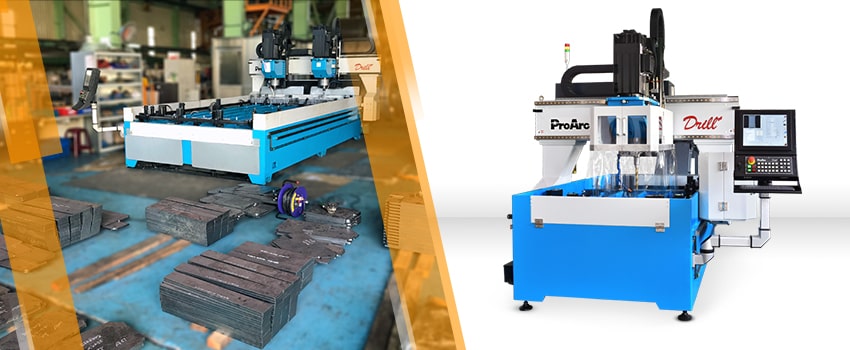

CNC Joint Plate Drilling Machine

- Home / Products / Cutting & Drilling/ CNC Joint Plate Drilling Machine

BROCHURES

Download our complete Company Profile

GET A QUOTE

OVERVIEW

CNC Plate Drilling Machines in UAE

It is commonly used in structural joint plates drilling services. Rockwood provide high quality CNC Joint Plate Drilling Machines in UAE

ProArc Drill+ table type CNC drilling machine is an automatic, efficient and high performance auto drilling machine. Rockwood Machinery is the best CNC drilling machine supplier in UAE.

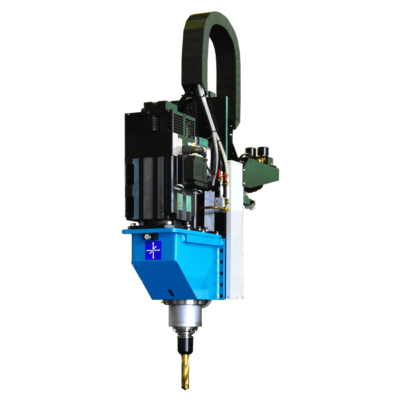

It constituted by:

- IPC based CNC controller

- Servo Z-axis lifter

- Servo drill spindle

- Auto tool length detector

- Auto plate thickness measuring device

We make drilling process easy, friendly and prevent mis-operation.

Features

AC Servo Z axis lifter

- Adopt ball screw feeding on Z axis with traveling speed 5,000 mm/min in 250mm stroke and is capable to support precise sequence control for primary, extremity and pecking process for auto drilling process.

- IPC based CNC controller

- Unique and intuitive GUI with touch panel

- Build-in Drill+ CAM in the controller

- Can read .dxf file and edit on job site directly

Quick release tool exchange device

- Change tool in seconds

Multi-task process

- Multi-home position can be defined for different jobs and edit in one drilling process

- Auto plate thickness detector

- Save measure time and keep accuracy

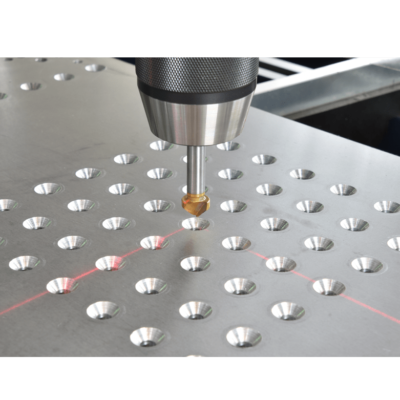

Cross line laser point unit

- Check position, support plate edge alignment and tech mode

Teach mode

- Learn parts with multiple drill points and capable to edit drilling process without drawing

- Auto tool length detector – one touch

- Save measurement time and keep accuracy

Specification

| Model | unit | Drill+166 | Drill+206 |

| Table size | mm | 1,600 x 600 | 2,000 x 600 |

| Working area 1 | 1 | 1,600 x 600 | 2,000 x 600 |

| Working area 2 | 2 | 750 x 600 | 950 x 600 |

| Z lifter effective stroke | mm | 250 | 250 |

| Plate thickness | mm | 100 | 100 |

| Positioning accuracy | mm | ±0.1 | ±0.1 |

| Positioning speed | m/min | 16 | 16 |

| Number of spindle | set | 1 | 1 |

| Spindle model | unit | DS-032 |

| Drive motor | hp | 7.5 |

| Drilling capacity | mm | Ø6 ~ 32?2 |

| Rotation speed | rpm | 10 ~ 3,000 |

| Effective length?1 | mm | 215 ~ 375 |

| Shank-standard | BT40-MT4 | |

| Shank-tapping (option 1) | BT40-TPM830?3 | |

| Shank-tapping (option 2) | TPC830?4 | |

| Shank-indexible drills (option) | BT40-SLA-OD?5 |

- Effective length: From spindle nose-end to drills end

- Max Ø40 mm when using high speed indexable drill

- Shank w/ tapping chuck

- Quick change tapping collets

- Shank w/ side lock holde

CNC drilling machine – Table type

ProArc Drill+1020, 1640 auto drill machine is an automatic, efficient and high performance CNC drilling machine.

It constituted by:

- IPC based CNC controller

- Servo Z-axis lifter

- Servo drill spindle

- Auto tool length detector

- Auto plate thickness measuring device

We make drilling process easy, friendly and prevent mis-operation.

Features

AC Servo Z axis lifter

- Adopt ball screw feeding on Z axis with traveling speed 6,000 mm/min in 350mm stroke and is capable to support precise sequence control for primary, extremity and pecking process for auto drilling process.

- IPC based CNC controller

- Unique and intuitive GUI with touch panel

Build-in Drill+ CAM in the controller

- Can read .dxf file and edit on job site directly

Quick release tool exchange device

- Change tool in seconds

- Multi-task process

- Multi-home position can be defined for different jobs and edit in one drilling process

- Auto plate thickness detector

- Save measure time and keep accuracy

Cross line laser point unit

- Check position, support plate edge alignment and tech mode

Teach mode

- Learn parts with multiple drill points and capable to edit drilling process without drawing

- Auto tool length detector – one touch

- Save measurement time and keep accuracy

Specification

| Model | unit | Drill+1020 | Drill+1640 |

| Table size | mm | 1,000 x 2,000 | 1,600 x 4,000 |

| Z lifter effective stroke | mm | 350 | 350 |

| Plate thickness | mm | 100 | 100 |

| Positioning accuracy | mm | ±0.1 | ±0.1 |

| Positioning speed | m/min | 16 | 16 |

| Number of spindle | set | 1 | 1~2 |

| Spindle model | unit | DS-050 | DS-080 |

| Drive motor | hp | 15 | 30 |

| Drilling capacity | mm | Ø6~50 | Ø6~80 |

| Rotation speed | rpm | 10 ~ 2,000 | 10 ~ 2,000 |

| Effective length?1 | mm | 215 ~ 375 | 215 ~ 375 |

| Shank-standard | BT40-MT4 | BT50-MT4 | |

| Shank-tapping (option 1) | BT40-TPM830?3 | BT50-TPM830?3 | |

| Shank-tapping (option 2) | TPC830?3 | TPC830?3 | |

| Shank-indexible drills (option) | BT40-SLA-OD | BT50-SLA-OD?4 |

- Effective length: From spindle nose-end to drills end

- Shank w/ tapping chuck

- Quick change tapping collets

- Shank w/ side lock holder

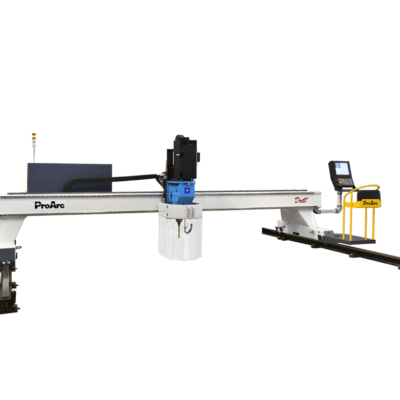

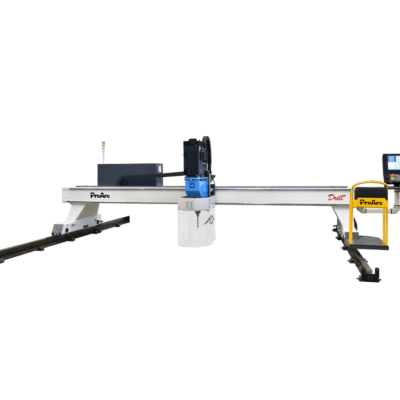

Drill+ CNC drilling machine (Gantry type) – Drilling and Tapping

ProArc Drill+ Gantry type auto drill machine is an automatic, efficient and high performance CNC drilling machine.

It constituted by:

- IPC based CNC controller

- Servo Z-axis lifter

- Servo drill spindle

- Auto tool length detector

We make drilling process easy, friendly and prevent mis-operation.

Features

AC Servo Z axis lifter

- Adopt ball screw feeding on Z axis with traveling speed 6,000 mm/min in 350mm stroke and is capable to support precise sequence control for primary, extremity and pecking process for auto drilling process.

- IPC based CNC controller

- Unique and intuitive GUI with touch panel

- Build-in Drill+ CAM in the controller

- Can read .dxf file and edit on job site directly

Quick release tool exchange device

- Change tool in seconds

Multi-task process

- Multi-home position can be defined for different jobs and edit in one drilling process

- Auto tool length detector – one touch

- Save measure time and keep accuracy

Cross line laser point unit

- Check position, support plate edge alignment and tech mode

Teach mode

- Learn parts with multiple drill points and capable to edit drilling process without drawing

Specification

Model unit Drill+25 Drill+30 Drill+35 Drill+40 Drill+50 Drill+60 Drill+80 Table size mm 1,700 x L 2,200 x L 2,700 x L 3,200 x L 4,200 x L 5,200 x L 7,200 x L Parking space mm 1,500 1,500 1,500 1,500 2,000 2,000 2,000 Z lifter effective stroke mm 350 350 350 350 350 350 350 Track Length/section mm 3,000 3,000 3,000 3,000 3,000 3,000 3,000 Plate thickness mm 100 100 100 100 100 100 100 Positioning accuracy mm ±0.1 ±0.1 ±0.1 ±0.1 ±0.1 ±0.1 ±0.1 Positioning speed m/min 16 16 16 16 16 16 16 Number of spindle set 1~2 1~2 1~2 1~2 1~2 1~2 1~2 Spindle model unit DS-050 DS-080 Drive motor hp 15 30 Drilling capacity mm Ø6~50 Ø6~80 Rotation speed rpm 10 ~ 2,000 10 ~ 2,000 Effective length?1 mm 215 ~ 375 215 ~ 375 Shank-standard BT40-MT4 BT50-MT4 Shank-tapping (option 1) BT40-TPM830?3 BT50-TPM830?3 Shank-tapping (option 2) TPC830?3 TPC830?3 Shank-indexible drills BT40-SLA-OD BT50-SLA-OD?4 - Effective length: From spindle nose-end to drills end

- Shank w/ tapping chuck

- Quick change tapping collets

- Shank w/ side lock holder