In many industries where products need identification and traceability, a nameplate engraving machine plays a crucial role. In the modern world of industrial name marking, there are two main types of engraving systems: dot peen marking and laser engraving. While some still use older methods like manual pantograph machines or computerized rotary engraving, the majority of engravers today prefer working with laser engraving or dot peen machines. In certain cases, a combination of both types is used. The demand for industrial and product marking has significantly increased among various producers. Businesses now aim to establish their products as recognizable brands with traceable features, making them stand out to potential customers.

In the industrial landscape of the United Arab Emirates (UAE), where precision, durability, and efficiency are paramount, the choice of nameplate engraving technology plays a crucial role in various sectors. Two prominent technologies that vie for supremacy in this arena are Laser Marking and Dot Peen Marking. In this comprehensive comparison, we delve into the intricacies of both technologies, exploring their strengths, applications, and considerations to aid businesses in making informed decisions for their nameplate engraving needs.

Understanding Laser Marking:

Laser marking technology represents the epitome of precision and versatility. It operates on the principle of utilizing a focused laser beam to alter the properties of a material’s surface, creating permanent and high-contrast markings. Here’s a closer look at the characteristics and applications of Laser Marking machines in UAE:

- Material Compatibility: Laser marking exhibits remarkable versatility, accommodating a wide range of materials commonly used in nameplate manufacturing. Whether it’s metals, plastics, glass, ceramics, or even certain types of organic materials, the laser’s adaptability stands out.

- Precision and Detail: One of the standout features of laser marking is its exceptional precision. This technology excels in creating intricate designs, small characters, and 2D codes. For industries requiring detailed engraving on nameplates, such as electronics or medical devices, laser marking is a go-to choice.

- Speed and Efficiency: In the fast-paced industrial landscape of the UAE, speed is often a decisive factor. Laser marking, known for its swift operation, is particularly suitable for high-volume production environments. The efficiency of laser technology contributes to streamlined workflows and quick turnaround times.

- Contactless Operation: Laser marking is a non-contact process, providing a distinct advantage in situations where delicate materials or surfaces are involved. The absence of physical contact minimizes the risk of damage to sensitive materials, making it an ideal choice for applications where the preservation of material integrity is paramount.

- Aesthetics and Versatility: The aesthetics of laser markings are notable for their clean and visually appealing nature. Smooth edges and high contrast contribute to the professional appearance of nameplates. Additionally, laser marking allows for a broad spectrum of designs and styles, making it versatile in meeting diverse aesthetic requirements.

Exploring Dot Peen Marking:

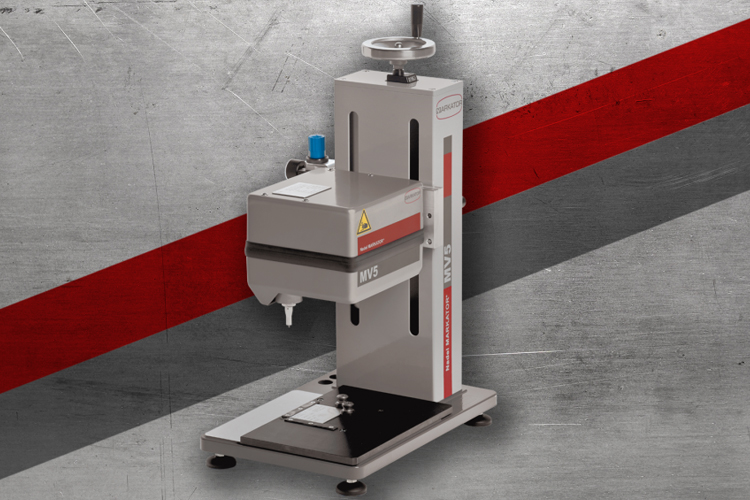

Dot peen marking, also known as dot matrix marking, takes a different approach to engraving. It involves a stylus striking the surface to create a series of dots, forming alphanumeric characters, logos, or 2D codes. Let’s examine the key aspects and applications of Dot Peen Marking in the context of nameplate engraving:

- Material Compatibility: Dot peen marking is well-suited for metals and plastics. While it may not boast the same extensive material compatibility as laser marking, it excels in applications where a deep and durable mark is essential. This makes it a popular choice for industries like automotive, aerospace, and metal fabrication.

- Precision and Legibility: Dot peen marking offers good precision, producing clear and legible engravings. While it may not match the intricate detailing achievable with laser marking, it delivers consistent and reliable results. The technology is particularly effective for creating permanent and indelible markings on various metal surfaces.

- Speed and Consistency: Dot peen machines operate at a slightly slower pace compared to lasers. However, they compensate with a level of consistency that is crucial for applications where reliability is paramount. The controlled impact of the stylus ensures uniform and reliable markings.

- Physical Contact: Unlike laser marking, dot peen involves physical contact with the surface. While this may be a consideration for materials sensitive to impact, the controlled nature of the stylus strike minimizes the risk of damage.

- Versatility in Industries: Dot peen marking finds its niche in industries such as automotive, aerospace, and metal fabrication, where durability and permanence are critical. It is often chosen for applications where the visual aesthetics of the mark are secondary to its longevity and resilience.

Factors Influencing the Choice:

- Material Type: The material used for nameplates is a significant factor in the choice between laser marking and dot peen marking. Laser marking’s versatility shines when dealing with a variety of materials, while dot peen excels in metals and certain plastics.

- Precision Requirements: If intricate details and small characters are essential for your nameplate engraving, laser marking provides the level of precision required. Dot peen, while precise, may be better suited for applications where extreme detail is not the primary concern.

- Production Volume: For high-volume production environments where speed is crucial, laser marking’s efficiency becomes a deciding factor. Dot peen, while consistent, may not match the pace of laser technology.

- Surface Sensitivity: The physical contact involved in dot peen marking might be a consideration for materials sensitive to impact. Laser marking’s non-contact nature can be advantageous in such cases.

- Budget Considerations: While both technologies offer excellent capabilities, budget considerations may play a role in the decision-making process. Dot peen machines can be more cost-effective for certain applications.

In the dynamic industrial landscape of the UAE, where innovation and precision are prized, the choice between laser marking and dot peen marking for nameplate engraving hinges on the specific needs of the application. For industries demanding intricate designs, versatility across materials, and swift production, laser marking stands out as the technology of choice. On the other hand, for applications prioritizing durability, permanence, and reliability, dot peen marking proves its mettle.

Ultimately, the decision should be guided by a thorough understanding of the materials involved, precision requirements, production volumes, and the specific demands of the industry. Whether a business opts for the non-contact precision of laser marking or the controlled impact of dot peen marking, the goal remains the same: to achieve durable, legible, and indelible nameplate engravings that stand the test of time in the vibrant industrial landscape of the UAE.

To know more about Rockwood: Leading the Way as Welded Studs Suppliers in UAE