Notching

BROCHURES

Download our complete Company Profile

GET A QUOTE

OVERVIEW

PIPE NOTCHING MACHINES IN UAE

Pipe Notching Machines allow you to quickly prepare bending and welding works at a fast pace while maintaining precision and reducing work piece damage. High efficiency, extended operating life, easy handling and low maintenance cost, exact profile matching with numerous tubes and notches, durability, and good performance are few characteristics of our pipe notching machines in UAE.

Belt grinder Metalwolff HighSpeed 75-D

Rockwood Machinery offers belt grinder Metalwolff HighSpeed 75-D grinding machine with high speed of 45 m/s and belt width 75 mm. Our grinding machine provides an excellent result for all your grinding jobs at a much faster rate. Changing the belt and working height is very simple and will take just seconds.

Rockwood Machinery offers belt grinder Metalwolff HighSpeed 75-D grinding machine with high speed of 45 m/s and belt width 75 mm. Our grinding machine provides an excellent result for all your grinding jobs at a much faster rate. Changing the belt and working height is very simple and will take just seconds.

Other features include:

- Double speed motor

- Rapid belt changing system

- Vibration free operation.

- Adjustable working height

- Incl. dust collection box.

- Incl. grinding belt 75×2000 mm.

- Top table for flat grinding + deburring

Technical Details

| BRAND | Metalwolff |

|---|---|

| TYPE | HighSpeed 75-D |

| MANUFACTURER | EMG BV |

| POWER | 400V, 3 phase |

| MOTOR | 3,3 KW |

| TWO SPEEDS | 22,5 m/s – 45 m/s !! |

Pipe Grinder 100 Triple Grind

The pipe grinding machine Metalwolff 100 Triple Grind is an innovative, multifunctional machine. On the front side there is a convenient pipe notcher, on the top a deburring table and on the back side a belt grinder. Changing from pipe notcher to belt grinder will take just seconds! The strong clamping system will provide an excellent result for all your grinding jobs!

The pipe grinding machine Metalwolff 100 Triple Grind is an innovative, multifunctional machine. On the front side there is a convenient pipe notcher, on the top a deburring table and on the back side a belt grinder. Changing from pipe notcher to belt grinder will take just seconds! The strong clamping system will provide an excellent result for all your grinding jobs!

Features

- Option 1: Pipe notching

- Option 2: Deburring table on top

- Option 3: Belt sander.

- Angle pipe notcher 30°-90° (0°-60°)

- Grinding roller 42,4mm standard.

- Grinding belt 100 x 2000 mm.

- Dust extraction optional.

Technical Details

| BRAND | Metalwolff |

|---|---|

| TYPE | 100 Triple Grind |

| MANUFACTURER | EMG BV |

| VOLTS & KW | 400V, 3 phase / 3KW |

| SPEED 1 | 1400 rpm (stainless steel) |

| SPEED 2 | 2800 rpm |

Belt Grinder Highspeed 150 D

The belt grinder Metalwolff HighSpeed 150-D is an innovative belt grinding machine with high speed. (45 m/s !!) The belt width is 150 mm. Changing the belt and working height is very simple and will take just seconds. Because this beltgrinder is a high speed machine you will finish grinding much faster. It will provide an excellent result for all your grinding jobs!

The belt grinder Metalwolff HighSpeed 150-D is an innovative belt grinding machine with high speed. (45 m/s !!) The belt width is 150 mm. Changing the belt and working height is very simple and will take just seconds. Because this beltgrinder is a high speed machine you will finish grinding much faster. It will provide an excellent result for all your grinding jobs!

Features

- Double speed motor.

- Rapid belt changing system.

- Vibration free operation.

- Adjustable working height.

- Incl. dust collection box.

- Incl. grinding belt 150 x 2000 mm.

- Top table for flat grinding + deburring.

Technical Details

| BRAND | Metalwolff |

|---|---|

| TYPE | HighSpeed 150-D |

| MANUFACTURER | EMG BV |

| POWER | 400V, 3 phase |

| MOTOR | 3,3 KW |

| GRINDING SPEED | 22,5 m/s – 45 m/s !! |

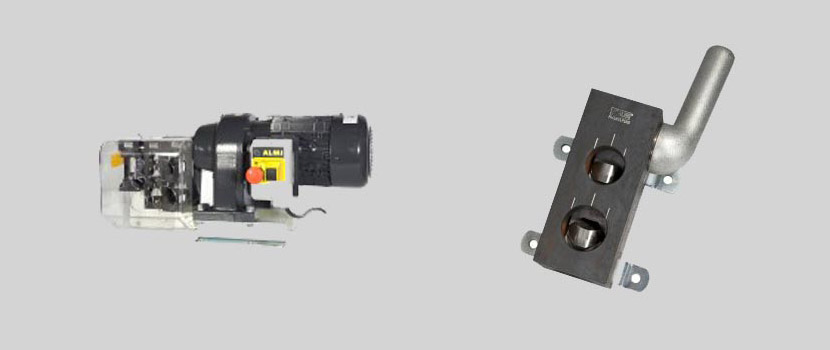

PIPE NOTCHER (TN-200E)

Do you make 90° notches in schedule 40 pipe all day, every day?

Do you make 90° notches in schedule 40 pipe all day, every day?

Then the TN-200E is for you. This electric tube notcher was specifically designed to notch schedule 40 pipe ranging in sizes from 1/4” to 2”. This 220 volt, single phase machine provides clean and fast notches.

Operation of the TN-200E is easy, simply inset the end of the pipe you need to cope, the TN-200E will notch one side and to notch the other side simply rotate the pipe 180° and reinsert. That is a perfect 90° notch in seconds.

Specifications

| ITEM NUMBER | TN-200E |

|---|---|

| NOTCHING CAPACITY (OD) | 13.7, 17.1, 21.4, 26.7, 33.4, 42.2, 48.3, 60.3 mm |

| NOTCHING CAPACITY PIPE | 6.35 mm |

| POWER | 220V, 1-Phase, 50Hz |

| SHIPPING WEIGHT | 105 kgs. |

| SHIPPING DIMENSIONS (INCHES) | 914 mm x 406 mm x 457 mm |

*specifications subject to change without notice.

MANUAL PIPE NOTCHER (TN-150M)

The TN-150M manual tube notcher has three set holes for three desired notches.

The TN-150M manual tube notcher has three set holes for three desired notches.

The machine is manually operated with the blade notching a set 90° notch to one section of the tube. To create the second notch the tube is to be rotated 180° with the same process then creating the overall final notch perfect for creating strong welding joints.

The three sizes of notch holes measure 1.25″ , 1.5″ and 0.75″ (31.75mm, 38.1mm, 44.5mm).

The machine can be bench mounted or taken onsite to perform perfect notches.

Specifications

| ITEM NUMBER | TN-150M |

|---|---|

| NOTCHING CAPACITY (TUBE) | 31.75, 38.1, 44.45 mm |

| POWER | Manual |

| SHIPPING WEIGHT | 9 kg |

| SHIPPING DIMENSIONS (INCHES) | 508 x 178 x 178 mm |

*specifications subject to change without notice.