Plate Rolling

- Home / Products / Bending & Forming / Plate Rolling

BROCHURES

Download our complete Company Profile

GET A QUOTE

OVERVIEW

Plate Rolling Machines in Dubai

Keeping abreast of the trends in bending and forming operations, we deliver high quality plate rolling machines in Dubai. Rockwood is proud to relies on Tommaso Seravesi’s collaboration, who has been designing bending machine, presses and flanging machines for over 50 years. Besides supervising the building stage of the Plate Rolling Machines, we have been leading the supply of highly- efficient plate rolling machines in Dubai.

The main objective of 1960 Seravesi Srl is that of supplying sheet metal forming machinery such as 3 and 4 rolls plate bending machines, presses and flanging machines, alongside the manufacturing of this constructing machinery, starting from its design down to the final testing and assembly on site with the utmost precision and care. We are the manufacturer of:

- Plate Bending Machines 3 Rolls With Variable Geometry And Double Pre-Bending;

- 4 Rolls Pyramidal With Double Pre-Bend;

- Hydraulic Press Presses With Mobile Piston And Fix Gantry;

- Presses With Fix Piston And Gantry;

- Presses With Mobile Piston And Gantry;

- Hydraulic Manipulators;

- Hydraulic Flanging Machines;

- Special Machine According To The Customer Request

Plate Bending Machines 3 Rolls

E79

The E79 is a hydraulic 3 roll plate bending machine composed of bottom rolls on horizontal axes and a top motorised roll with hydraulic vertical movement.

The E79 series bending machines are available with a capacity from 25mm to 300mm and roll length from 1000mm to 6000mm.

The E79’s Key Features

BENDING of medium and large thicknesses (recommended from 25 mm to 300mm). It is the ideal machine due to its particular design because it has reduced sizes and a shorter straight section compared to the four rolls, and thanks to the tilt of all three rolls, there is the possibility to perform even complex conical processes, in a much easier way than with four rolls.

The PRE-BENDING obtained is excellent thanks to the high push of the top roll which is used in this phase as a bending press.

REVOLUTION of its geometry: In fact, the bottom rolls move horizontally and are independent from one another with variable pitch, whilst the motorised top roll moves vertically.

VERSATILE: increasing the distance between the bottom rolls very thick plates can be bent, whilst decreasing the distance it is possible to bend thin plates and so create tubes with a small diameter. Having a roll plate bending machine with variable axes is like having two machines in one.

INDEPENDENT: the movement of the three rolls easily allows the creation of cones. The bottom rolls and top roll can tilt independently up to 2°.

SAFE: for the safety of the operators, we made it possible, thanks to its particular geometry, that the plate stays in a horizontal position during every work phase. Furthermore, the machine is set up with an emergency stop push button to immediately stop its movement.

SIMPLE to use and maintain thanks to easy accessibility of the hydraulic parts and the diagnostics on the control panel, that are always within reach of the operator.

DIMENSIONS small and compact in comparison to other bending machines that do not require the foundation pit up to a certain size.

Plate Bending Machines 4 Rolls

RI72

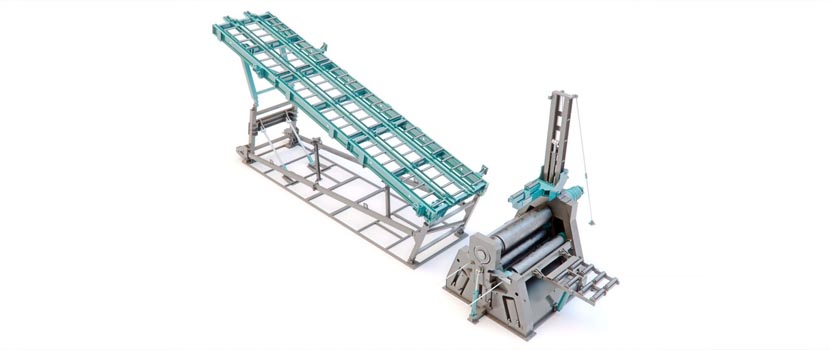

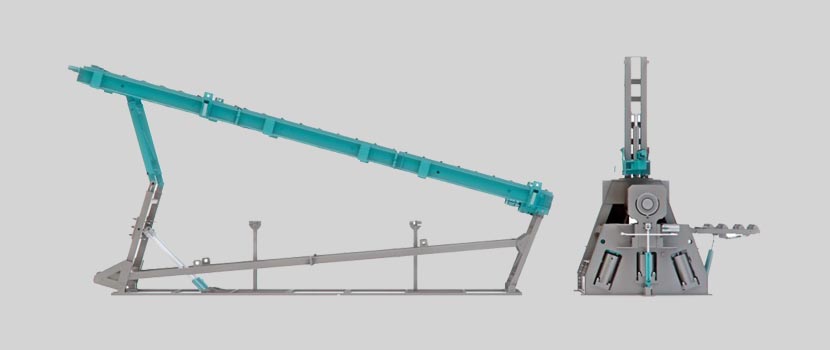

The RI72 is an hydraulically operated 4 roll plate bending machine with double pre-bending. The rolls have a linear movement along bronze guides.

The RI72 series bending machines are available with a capacity from 25mm to 300mm and roll length from 1000mm to 6000mm.

The RI72’s Key Features

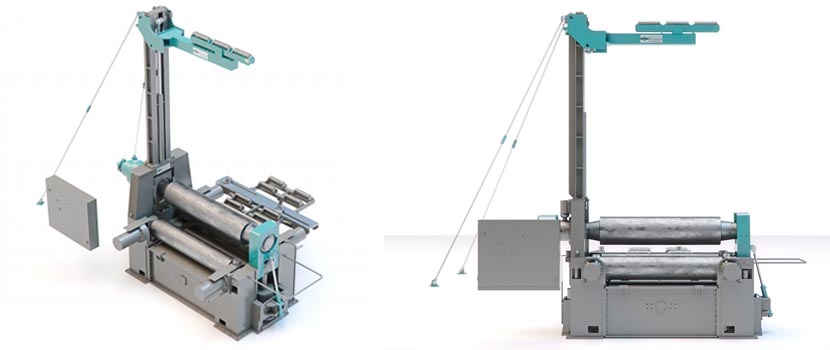

PRE-BENDING is perfect with a minimum straight section (3-4 times shorter than planetary “PSG” technology) due to the high power force of the cylinders on the bottom rolls, that thanks to the linear motion are fitted directly under the rolls and do not use any system of levers.

Positioning PRECISION of the rolls maintained over time thanks to the linear guide system. The bottom rolls are guided within the structure of the machine, eliminating the possibility of clearance due to machine wear and tear, contrary to what happens on machines with a planetary (PSG”)/lever system.

CANCELLATION of the sliding friction of rolls, ensured by a system of lubricated bronze guides.

PARALLELISM of bottom rolls perfectly assured by a system that uses a two linear potentiometer for each roll. The rolls are independently adjustable and tilt easily to allow for the execution of cone bending.

ROBUSTNESS is characterised by solid structural steelwork and linear structures.

SPEED and RELIABILITY of high quality work

EASY to use and maintain thanks to easy accessibility of the hydraulic parts and the diagnostics on the control panel, that are always within reach of the operator.httpss://www.youtube.com/watch?v=2OmW9gJxJjQ

PULSANTE-DOWNLOAD-TECH-TABLE

PULSANTE-REQUEST-A-QUOTE

SCHEMI-FUNZIONAMENTO-4-RULLI

How to use it

- Insert the plate between the rolls

- Align the plate with the side roll (angled)

- Clamp the plate between roll D and C

- Create the pre-bending using roll A

- Continue with forming the required diameter of plate between the rolls using both roll A and roll B.

- Create the second pre-blending using roll B.